|

|

|

|

| CONCENTRIC BUTTERFLY VALVE |

| HOME > PRODUCTS > CONCENTRIC BUTTERFLY VALVE |

|

|

|

|

| BRIEFS |

Product Product |

Concentric Butterfly Valve |

Type Type |

Wafer, Lug, Flanged Type |

Size Size |

50A~1200A / API, DIN, JIS |

Materials Materials |

Ductile, Carbon, Stainless, Bronze |

Operation Operation |

Lever, Gear, Actuator |

Origin Origin |

Power Plant, Chemical Industry, Crude Oil etc,. |

Factory Factory |

Kimhae City, Korea |

|

|

|

| OTHER PRODUCTS |

|

|

| CLASSIFICATION BY CONNECTION TYPE |

|

| Wafer |

Valve to be installed with long bolts between the flanges at adjacent pipe without flange on the valve.

Ease handling and light weight.

Ease installation, less bolt quantity and low cost.

lnconvenient maintenance of adjacent pipe. |

| Lug |

Ring shape bolt hole for bolting with flange.

Keep pressure inside during repairing adjacent one side pipe.

Different flange shape.

Possible damage on full face gasket.

Hard repairing of corroded bolt.

More man-hour for installation. |

| Flanged |

Both ends with complete flange.

Suitable to general pipe flange.

Suitable for shipside valve in the ship.

Heavy weight.

Same installation as ordinary valve. |

|

|

| PRODUCT FEATURES |

|

|

|

|

|

100% Made in Korea (Casting & Machining for BODY, DISC, SEAT, STEM)

KB Valve Technology uses domestic rubber materials such as Donga Tire CMB and Korea CMB companies. We use optimal high elasticity EPDM rubber seat product for butterfly valves with strong properties for water resistance, chemical resistance and ozone resistance with Advanced and Optimized Mixing Technology.

- Features and Advantages

● We guarantee full close without leakage by carrying out factory tests under all the specified pressure.

● The primary sealing formed by the contact surfaces of the seats, stem and hub is kept a complete stem sealing at the

specified pressure and the body is completely separated from the fluid.

● It provides complete sealing to all parts of the disk by processing the polished disc edge of the disk in a flat structure on

top and bottom of the seat.

● The O-RING formed on the seat, maintains a firm flange airtightness and no need to use of gasket between flanges.

● Stem structure to be able to do well for strong force and disk operation.

● Depending on the order specification, seat material can be used with various materials, e.g. EPDM, BUNA-N, etc.

|

|

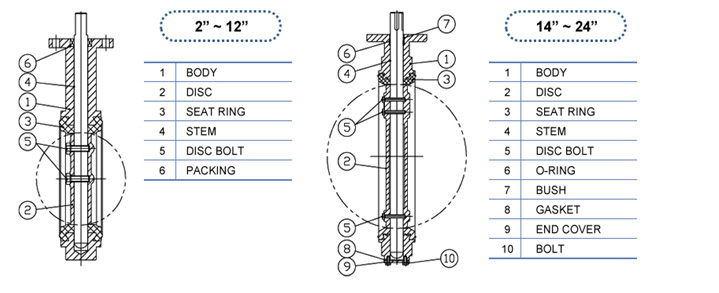

| - Schema of Concentric Butterfly Valve |

| The valve shall be a 90 turn clockwise to close, non-jamming, resilient seated valve for zero leakage service. |

The valve shall be torque seated and designed in such a manner that the disc can not be rotated the seat

without the actuator.

|

Also this valve enables the fluid perfect shut-off regardless of the flow direction

|

| - General Applications |

Shipbuilding, water works, heating and ventilation, power plants, oil refinery Chemical plants etc.

|

| - Special features of KB valve's products |

| * a groove along the lining between seat and body prevents strong friction |

| * minimized contact surface between seat and disc provides enhanced durability |

| * Various of seat material would be adopted such as EPDM, NBR, VITON |

|

|

|

| TRADE TERMS |

|

| - Payment Terms |

At Sight L/C, T/T |

| - Delivery Time |

Within 30 days after your payment |

| - Min. Order Qty |

1 units |

| - Certificates |

ISO9001, API 609, CE |

| - Other |

|

|

|

|

|